| Copper based wear resistant alloys |

Wear-resistant copper alloy is a kind of wear-resistant alloy based on copper. It has two categories: bronze and brass. Because of its good thermal conductivity, conductivity and corrosion resistance, it is widely used in friction system, especially in conductive devices. Brass and bronze for the same purpose, mainly used for gear (worm wheel), bearing, shaft sleeve and other wear-resistant parts. Beryllium bronze (2% beryllium) with high copper content in bronze is the best kind of wear-resistant copper alloy. Because of its hardness, fatigue strength and corrosion resistance, beryllium bronze is used as bearing and precision gear material at high speed and high temperature (up to 300℃).

Tin bronze and aluminum bronze are modified by adding a small amount of other elements in binary alloys such as Fe, Ni, Zn, Mn, P and so on. In addition to the solution strengthening phases, they also contain some hard intermetallic compounds, which have high wear resistance and are often used in the manufacture of bushing jackets of Babbitt alloy.

Under the condition that the mechanical properties or the technological properties of brass are not changed, by adding Sn, Al, Mn, Pb or Si etc, brass can be formed to be tin brass, Al brass, Pb brass or Si brass. These additive elements play a significant role in improving the corrosion resistance and wear resistance and friction reduction properties of the alloy.

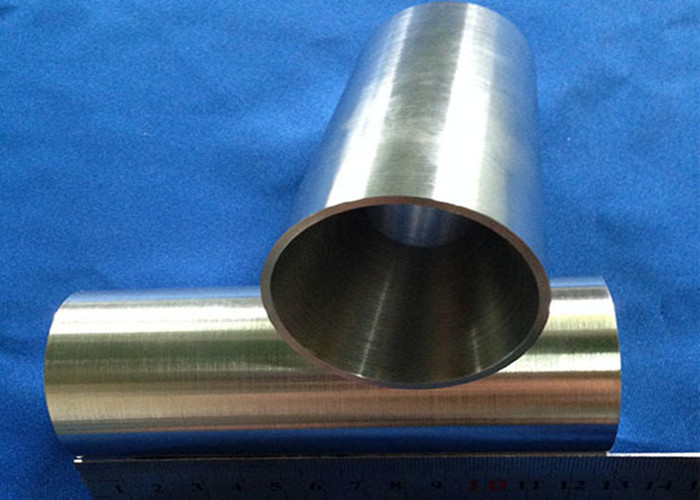

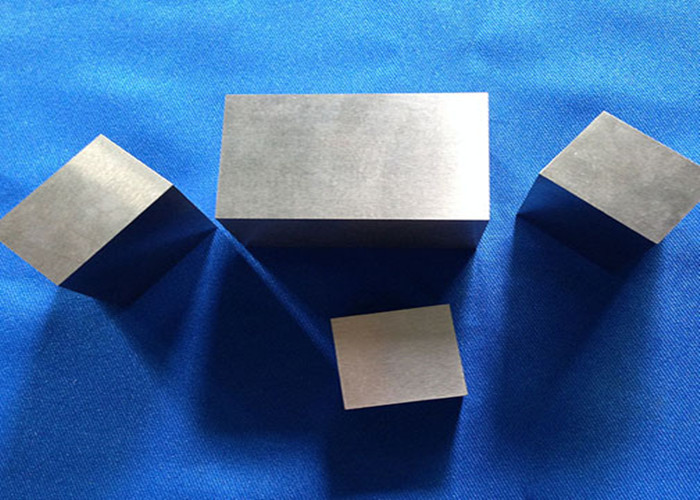

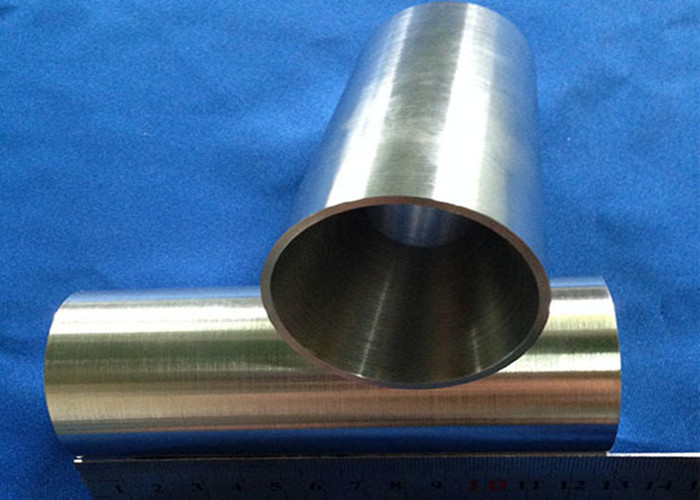

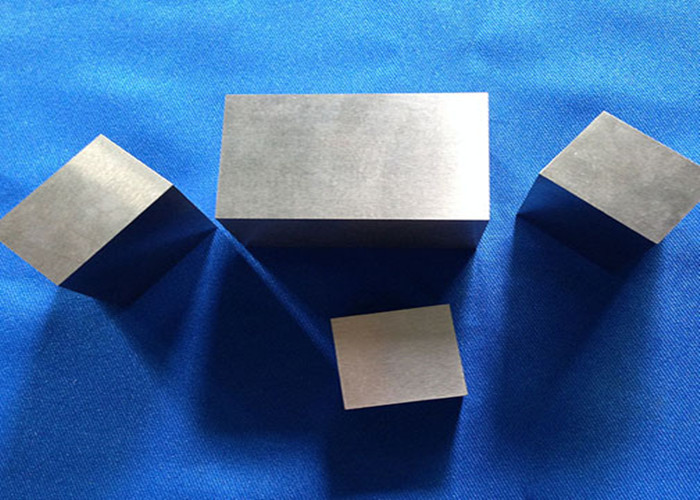

Product: forging, bar, wire, plate, strip, pipe, finish machined part

Regular grade:AMPCO®8, AMPCO®15, AMPCO®18, AMPCO®21, AMPCO®22, AMPCO®25, AMPCO®642, AMPCO®M4 ETC.

| Ni-base wear resistant alloy |

The main alloy elements of Ni based wear resistant alloys are chromium, molybdenum and tungsten, and also a small amount of niobium, tantalum and indium. The chemical composition of is (%): C 0.10-0.20, Mn 0.25, Si 0.60, Cr 14.00-17.00, Mo 4.50-6.00, Al 2.5-3.50, Fe 8.00-12.00, Ti 1.50-2.50, Ni remainder. The tensile strength at 820℃ is 520MPa, and the elongation is 3%. Besides its wear resistance, its oxidation resistance, corrosion resistance and weldability are also good. This material is generally used for wear-resistant parts in air or low-lubricating liquids, such as valves, pumps, pistons, rings, seals, brakes, tappets, blades and blades in petrochemical equipment, atomic energy equipment, jet aircraft and internal combustion engines etc. It can also be used as coating material by surfacing and spraying. The process is coated on the surface of other matrix materials. Ni based alloy powders consist of self fluxing alloy powder and non self fluxing alloy powder.

| Stellite wear resistant alloys |

Stellite is a cemented carbide which can withstand various types of wear and corrosion as well as high temperature oxidation. It is commonly referred to as cobalt chromium tungsten (molybdenum) alloy or cobalt based alloy. Stellite alloy is a kind of alloy with cobalt as the main component, containing a considerable amount of nickel, chromium, tungsten and a small amount of alloying elements such as molybdenum, niobium, tantalum, titanium, lanthanum, and occasionally iron. Depending on the composition of the alloys, they can be made into welding wires, powders for hard surfacing, thermal spraying, spray welding and other processes, as well as castings, forgings and powder metallurgical parts.

Typical brands: Stellite 1, Stellite 3, Stellite 4, Stellite 6, Stellite 8, Stellite 12, Stellite 20, Stellite 21, Stellite 25, Stellite 31, Stellite 100, Stellite 250, Stellite 694, Stellite SP1040, etc.

For casting turbine blades and guide blades for aerojet engines and turbochargers, typical stellite alloys are HA-21, K4, HA-188, X-40, X-45, WI-52, Mar-M509, FSX-414, etc.

S-186 is wrought stellite alloy for forging turbine blades, L-605 plate is used for making for combustion chambers and ducts.

Normal typical stellite alloys:Stellite 6, Stellite 6B, Stellite 6K, Stellite 25,

Stellite 6B is mainly for high impact pulp agitators, critical directional drilling tools, or aerospace component.

Stellite 6K is mainly for knife, scraper blades etc.

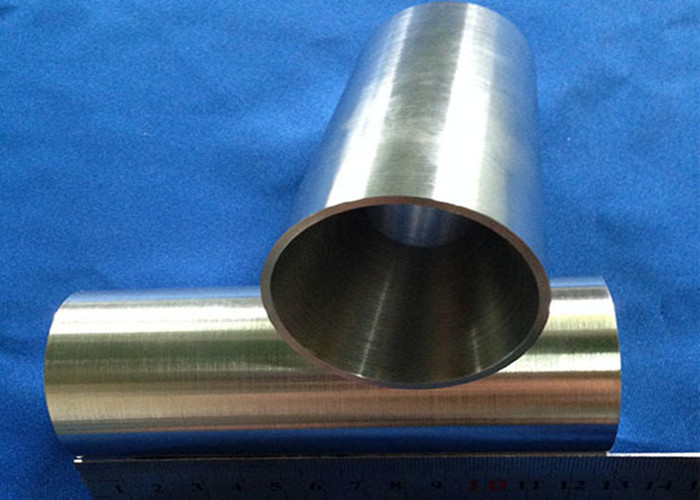

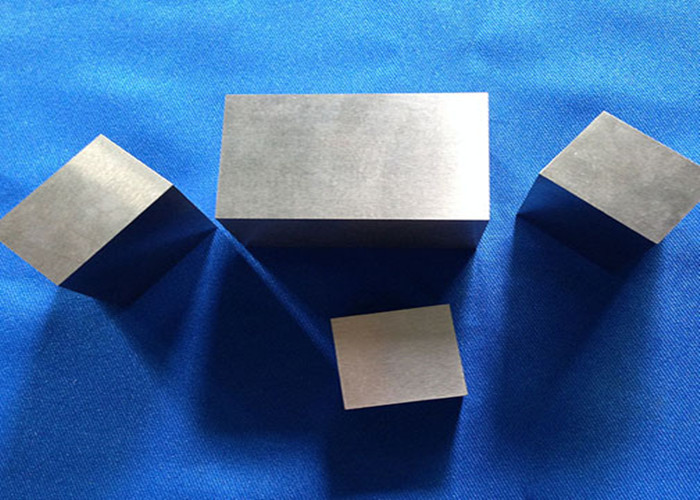

Product:bar, ring, pipe, finish machined part.